SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

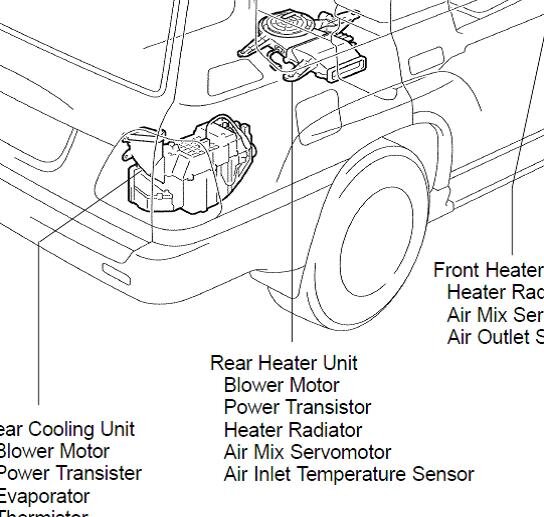

Here's my Glind mounting in the engine bay.

Mounted mine on the inlet manifold as its easier to get at the heater plumbing there. To the right you can see the water pump.

The HE water i/o connections are via garden hose click lock fittings underneath the front Roo bar.

Strongly suggest that you use at least three if not the four mounting tabs. If you use just two, eventually they'll snap with vibration. Bit of weight there with the water and copper.

You can see some of the heater hose routing here-

Out of the block into the H/E

HE return to cabin heater.

Thanks Womblingfree.....I'll take a look at that fitting option. I didn't even try that as I thought there would be insufficient space under the bonnet.