good evening all, right to get this blog started i will tell you whats going on,

i am a great fan of getting away for the weekend laning/wild camping or even glamping and the regular outings at billing, and the overland show at stratford this year, i have been building an extension on the back of the house for the last year and a half, slow i know. so i have had a decent break from the lanes,

my last build was a magolina roof tent copy, which i have used loads of times ( untill i washed the thing in a mild soap water) and lost the water repellant propertys, still i have had some great nights out, and would go out again, anyway the reason im here.

i want to build an off road camper, so where do you begin, well i looked at trailers , sankeys, farm trailers, all sorts of military trailers and just could not find anything i could use, there were plenty of trailer axles with land rover pcd hubs so i looked at engineering adapters to change to land cruiser fitment, still some mileage on that idea ,

well after cruising through fleabay i found an rear axle from a nissan nivara, same stud pattern, and the thing that caught my eye, the axle was not the traditional casting type then milled afterwards, this axle was a 75mm 5mm walled steel pipe so to speak, great i can chop the diff out of the middle and fab in my own tube and set the track the same as my 80 winner all round, well thats what i thought, there was a bit of work involved but that is the fun part,

i have posted this blog on another site and found no response except tim, who i hope will pick it up on here

here goes please ask questions and if you have any ideas let them flow im a ground worker in construction, and love being able to fab up my own equipment from roof tents, winch bumpers,roof racks, and side exit exhaust,

this camper is being built by me and my infamous brother in law paul.

as the wife comes out some times for a spot of wild camping i have to fit some luxury like hot water, toilet, shower, heat, and power i dont want a souped up caravan, i want to build the b----- thing to go where i want it to go and park where i want

i have some pics just got to see how the hell i post, bear with me, and apoligies for the spelling and grammer

View attachment 10327View attachment 10328

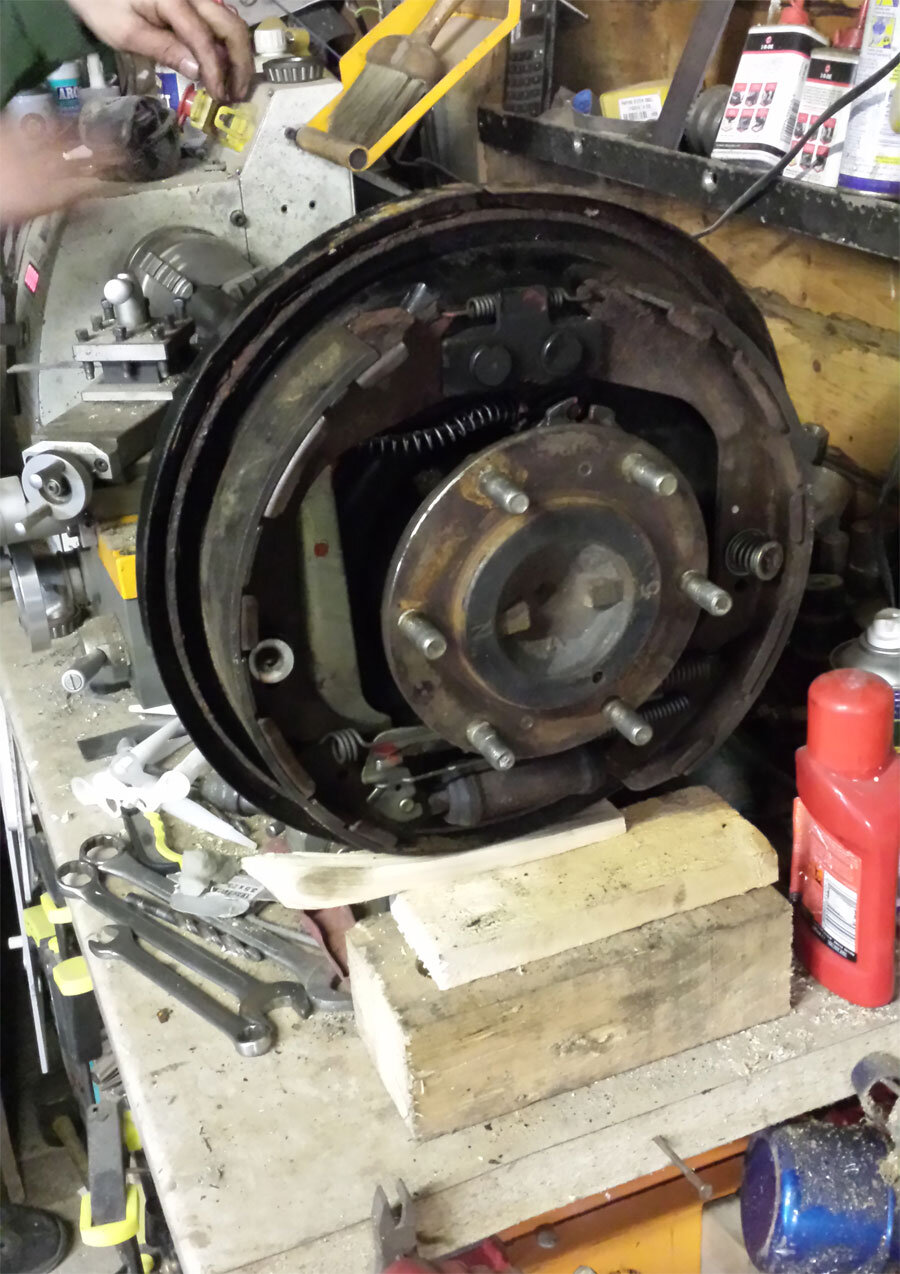

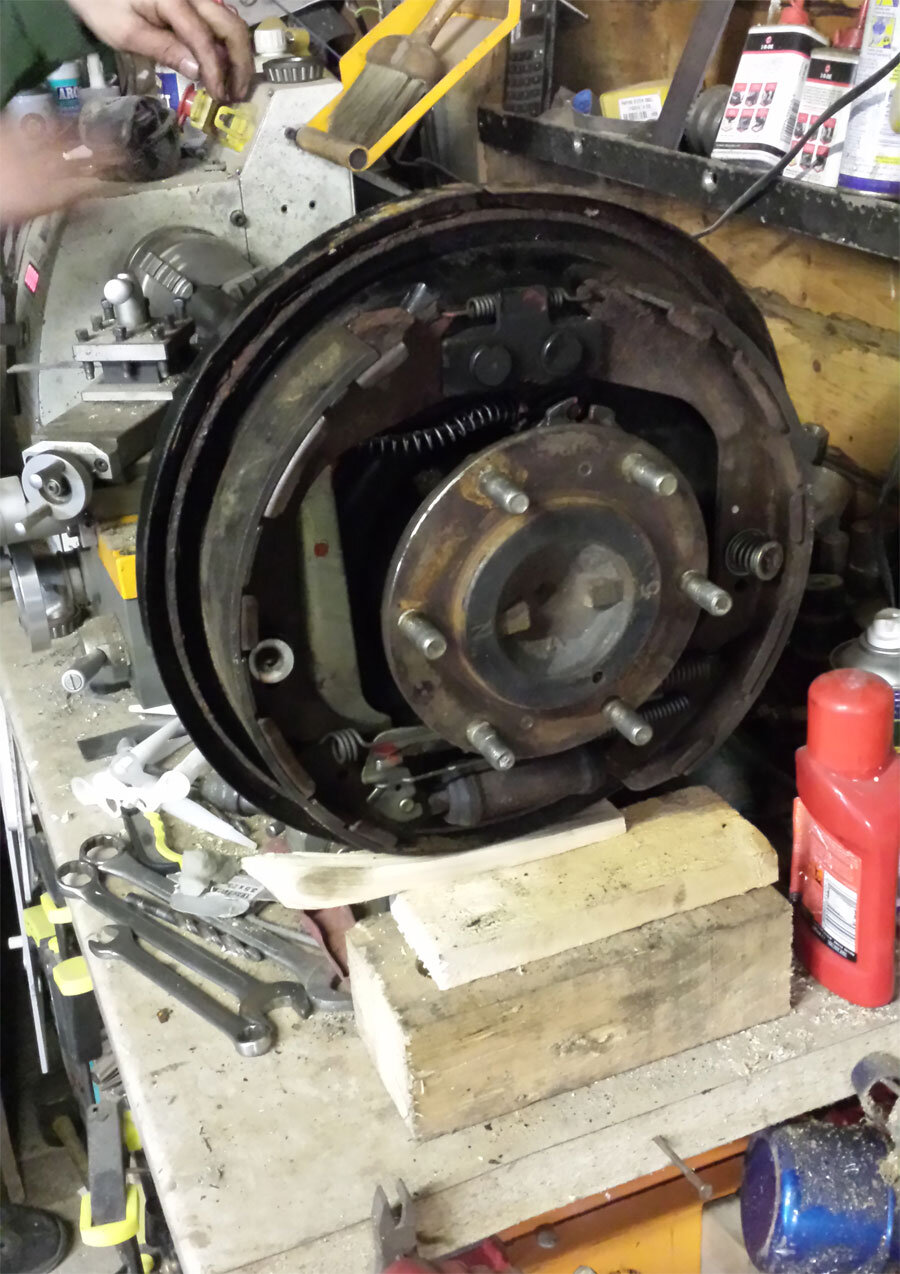

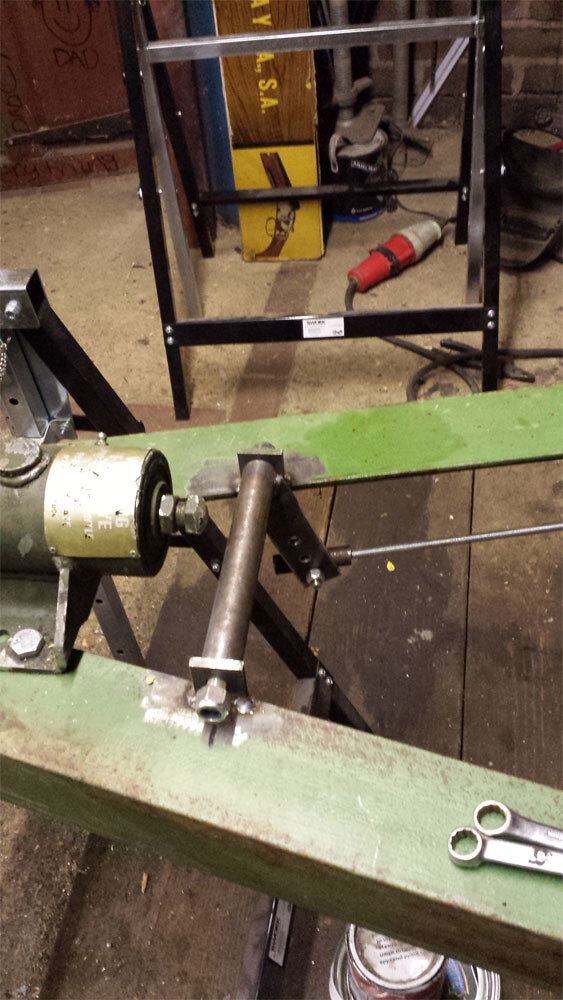

this is our first problem to over come, a floating half shaft, with one bearing in the hub end, this was not enough and i wasnt going to take the chance running on one, so i searched for a bearing to fit in the original axle tube to carry the shaft so i could cut off the excess, what a pain there is a limit to what you can buy, the only one was 62mm out side and 32mm internal the shaft was 33.75 so we had to get it in to the lathe, this will get some laughs,

i managed to get hold off a 75mm steel tube with a 5mm wall to use as a sleeve, i drilled out the middle and fitted an oil filler point as the new bearings are open faced and i need to lube

this is the bearing fitted and the shaft cropped, all the old brackets were cut off and reused as i want to use the original brakes, it was welded in so it wont move and it sits against the shoulder we turned down in the lathe

the welding is buy paul hes first class, the 19mm holes were just to get that extra fix the the original axle outer tube

job done, these wheels are 35inch and im getting excited, you will have to remember this has not been down on paper so we do discuss as much as possible and we do get some silly mistakes.

the next bit was to fab the mounts for the springs.... easy bit

we had tube lying around for the bushes and some 4mm flat for the hangers, well thats what im calling them, profiled,drilled, folded, then welded on to the chassie, which is a 100mm x 50mm box 4mm wall

the chassis is finished at 2.4 long x 1.250 then out riggers taking it out to 1.800 wide

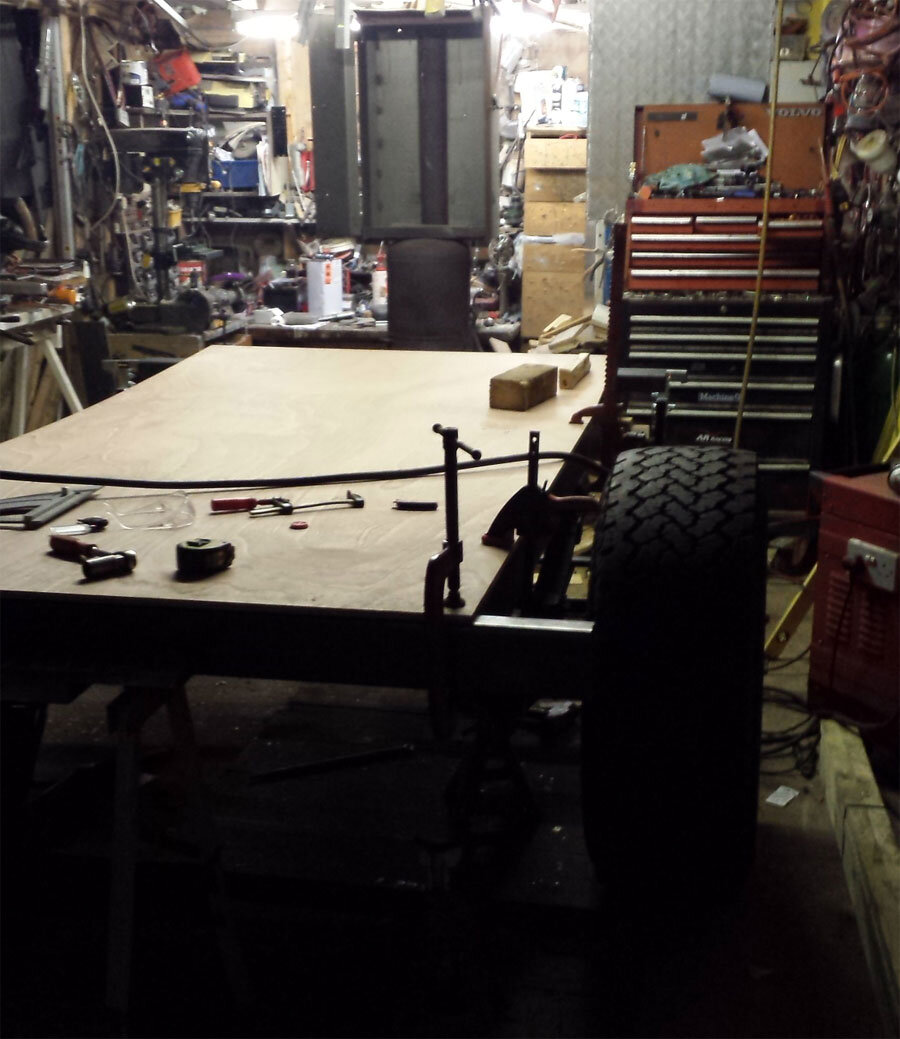

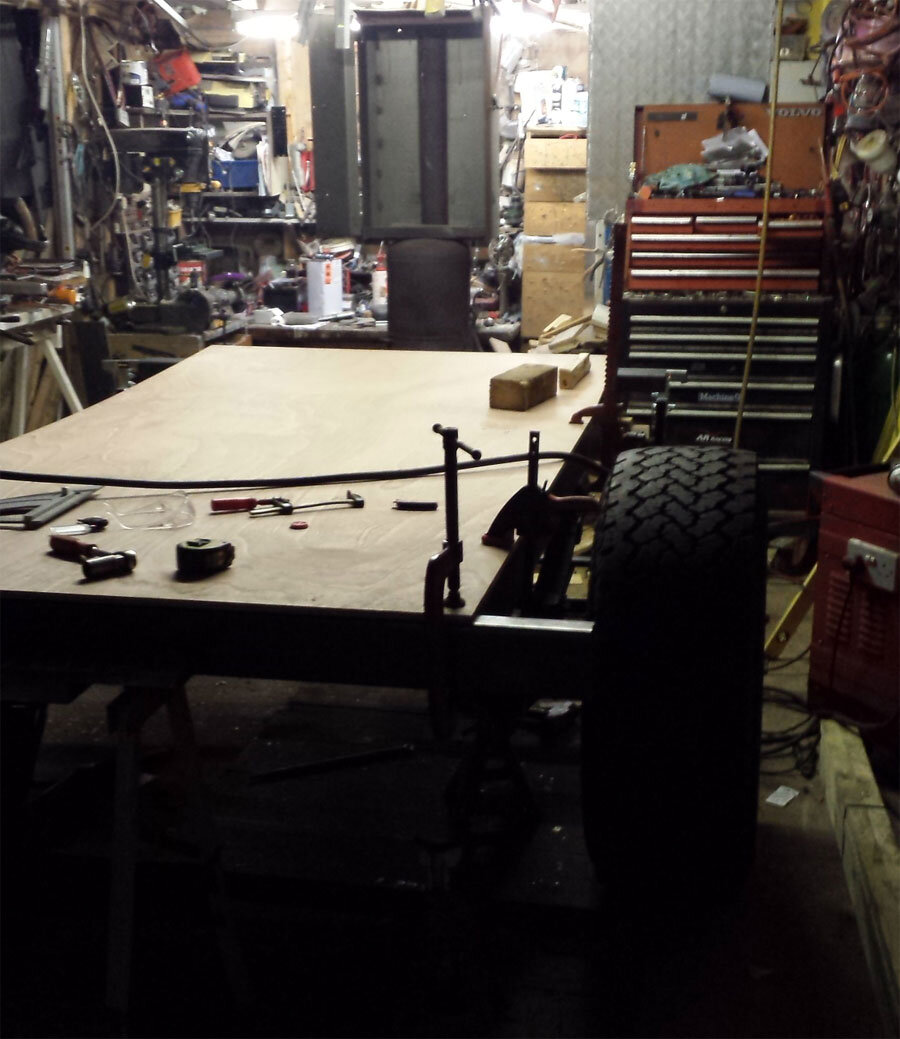

this is the biggest square we could find to set up the chassie 8x4 marine ply

the chassie now set we went about the a frame, which has to be long for the angles shes going to be getting in to.

the last time we set up an a frame we used string lines, b-----ks to that i got me a laser and it went as sweet as a nut once we set up center on the chassie

you can see the laser beam on the rear of the bradley hitch, this is only set upside down for welding purposes

well thats all for now gents catch you all soon

i am a great fan of getting away for the weekend laning/wild camping or even glamping and the regular outings at billing, and the overland show at stratford this year, i have been building an extension on the back of the house for the last year and a half, slow i know. so i have had a decent break from the lanes,

my last build was a magolina roof tent copy, which i have used loads of times ( untill i washed the thing in a mild soap water) and lost the water repellant propertys, still i have had some great nights out, and would go out again, anyway the reason im here.

i want to build an off road camper, so where do you begin, well i looked at trailers , sankeys, farm trailers, all sorts of military trailers and just could not find anything i could use, there were plenty of trailer axles with land rover pcd hubs so i looked at engineering adapters to change to land cruiser fitment, still some mileage on that idea ,

well after cruising through fleabay i found an rear axle from a nissan nivara, same stud pattern, and the thing that caught my eye, the axle was not the traditional casting type then milled afterwards, this axle was a 75mm 5mm walled steel pipe so to speak, great i can chop the diff out of the middle and fab in my own tube and set the track the same as my 80 winner all round, well thats what i thought, there was a bit of work involved but that is the fun part,

i have posted this blog on another site and found no response except tim, who i hope will pick it up on here

here goes please ask questions and if you have any ideas let them flow im a ground worker in construction, and love being able to fab up my own equipment from roof tents, winch bumpers,roof racks, and side exit exhaust,

this camper is being built by me and my infamous brother in law paul.

as the wife comes out some times for a spot of wild camping i have to fit some luxury like hot water, toilet, shower, heat, and power i dont want a souped up caravan, i want to build the b----- thing to go where i want it to go and park where i want

i have some pics just got to see how the hell i post, bear with me, and apoligies for the spelling and grammer

View attachment 10327View attachment 10328

this is our first problem to over come, a floating half shaft, with one bearing in the hub end, this was not enough and i wasnt going to take the chance running on one, so i searched for a bearing to fit in the original axle tube to carry the shaft so i could cut off the excess, what a pain there is a limit to what you can buy, the only one was 62mm out side and 32mm internal the shaft was 33.75 so we had to get it in to the lathe, this will get some laughs,

i managed to get hold off a 75mm steel tube with a 5mm wall to use as a sleeve, i drilled out the middle and fitted an oil filler point as the new bearings are open faced and i need to lube

this is the bearing fitted and the shaft cropped, all the old brackets were cut off and reused as i want to use the original brakes, it was welded in so it wont move and it sits against the shoulder we turned down in the lathe

the welding is buy paul hes first class, the 19mm holes were just to get that extra fix the the original axle outer tube

job done, these wheels are 35inch and im getting excited, you will have to remember this has not been down on paper so we do discuss as much as possible and we do get some silly mistakes.

the next bit was to fab the mounts for the springs.... easy bit

we had tube lying around for the bushes and some 4mm flat for the hangers, well thats what im calling them, profiled,drilled, folded, then welded on to the chassie, which is a 100mm x 50mm box 4mm wall

the chassis is finished at 2.4 long x 1.250 then out riggers taking it out to 1.800 wide

this is the biggest square we could find to set up the chassie 8x4 marine ply

the chassie now set we went about the a frame, which has to be long for the angles shes going to be getting in to.

the last time we set up an a frame we used string lines, b-----ks to that i got me a laser and it went as sweet as a nut once we set up center on the chassie

you can see the laser beam on the rear of the bradley hitch, this is only set upside down for welding purposes

well thats all for now gents catch you all soon

Is this something you built a while ago and only just got round to showing us?

Is this something you built a while ago and only just got round to showing us?