AndyCook

Well-Known Member

A couple years ago the rear difflock stayed on when i used it to get unstuck in deep snow.

nothing would unlock it - jacked it up, turned wheels, reversed it etc

at the time i didnt know about the end cap for the accuator rod on side of diff, and instead i proceeded to remove the difflock accuator motor assembly and it fell apart... corroded...

i got a nice new replacement one.

since then i have used the rear difflock in anger a few times a year - snow, laning etc

and always activate it once a month to make sure things still moving.

last week in Lakes I needed the locker to get up some tricky rockslabs, and even then had both back wheels slipping.

back on the road i soon realized the rear difflock was still engaged, even though i had turned it off at dial and lights had gone off..

this time i removed the rod end cap on diff (needed an Irwin stud extractor to remove one bolt after it rounded off head when cheap socket split...

i pulled rod out the last 5mm with mole grips.

I used the rear difflock again in Peak district and it disengaged OK (i had also bought a new accuator from milners that morning but not fitted it!)

back home and with vehicle on axle stands i tested locker and it stayed locked again, even with turning control dial off-on-off etc

i removed end cap and pull the rod the last bit again to disengage - since it was moving, enough to lock OK but not quite moving out enough to unlock,

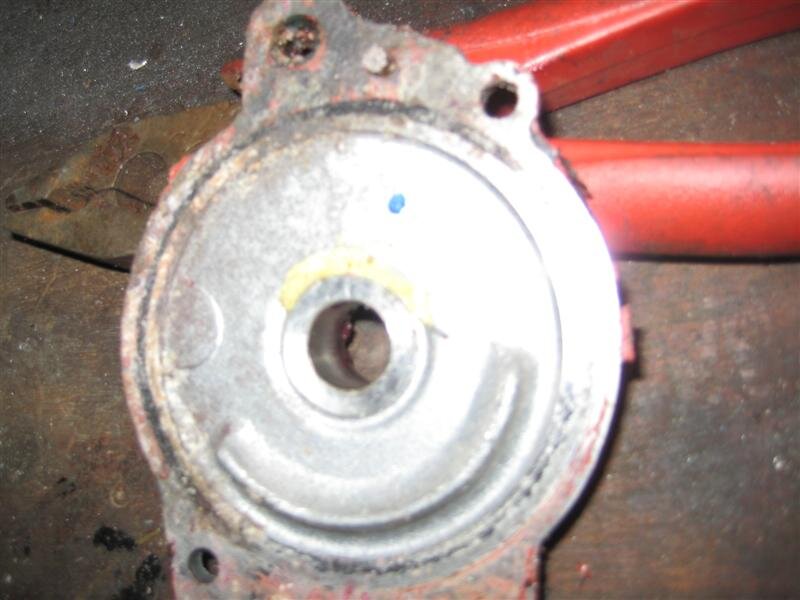

carefully i removed the accuator unit OK, pulled the accuator rod all way to end stop in off and refitted accuator (after motoring it on-off-on-off etc

this time it still locked ok, but 1 in 6 attempts it wouldnt unlock. but this time if turned cab control on-off-on, it unlocked after a few attempts. so is still a bit unreliable, and i cant be sure it will unlock properly everytimg its used.

i fitted the new unit and it worked flawlessly

so am am painting the new unit, and will fit it.

i will probably open the unreliable one and try and see what can be stopping the thing from fully unlocking everytime,

any ideas? i seem to remember there is a spring in there, but its only used for the locking motion?

nothing would unlock it - jacked it up, turned wheels, reversed it etc

at the time i didnt know about the end cap for the accuator rod on side of diff, and instead i proceeded to remove the difflock accuator motor assembly and it fell apart... corroded...

i got a nice new replacement one.

since then i have used the rear difflock in anger a few times a year - snow, laning etc

and always activate it once a month to make sure things still moving.

last week in Lakes I needed the locker to get up some tricky rockslabs, and even then had both back wheels slipping.

back on the road i soon realized the rear difflock was still engaged, even though i had turned it off at dial and lights had gone off..

this time i removed the rod end cap on diff (needed an Irwin stud extractor to remove one bolt after it rounded off head when cheap socket split...

i pulled rod out the last 5mm with mole grips.

I used the rear difflock again in Peak district and it disengaged OK (i had also bought a new accuator from milners that morning but not fitted it!)

back home and with vehicle on axle stands i tested locker and it stayed locked again, even with turning control dial off-on-off etc

i removed end cap and pull the rod the last bit again to disengage - since it was moving, enough to lock OK but not quite moving out enough to unlock,

carefully i removed the accuator unit OK, pulled the accuator rod all way to end stop in off and refitted accuator (after motoring it on-off-on-off etc

this time it still locked ok, but 1 in 6 attempts it wouldnt unlock. but this time if turned cab control on-off-on, it unlocked after a few attempts. so is still a bit unreliable, and i cant be sure it will unlock properly everytimg its used.

i fitted the new unit and it worked flawlessly

so am am painting the new unit, and will fit it.

i will probably open the unreliable one and try and see what can be stopping the thing from fully unlocking everytime,

any ideas? i seem to remember there is a spring in there, but its only used for the locking motion?

.

.