Don't like the adverts? Click here to remove them

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project 80: Codename Grey Ghost

- Thread starter Chris

- Start date

No Gary, been there done that. Not re gearing again! I am on 35's but they're 315.75.17. I'd quite like to go 315.75.16 But we'll see.

Rear shock plates were dead easy because I only changed the suspension last year. Every thing still greased. Now getting them out last year when I put the Ironman on wasn't as bad as some I have done. I seem to recall I used 6 sided sockets and long extensions to get the big breaker bar on after soaking the top nuts with some pen oil. If you have a nut runner, impact driver, airtool type thing you can save some elbow grease. Also being on a ramp would make a difference to laying on the drive. But all in all, I've had worse trucks to work on. If the plate wasn't removable, I wouldn't even try to undo the top nut. I just use the power hacksaw and cut through the top spindle.

Rear shock plates were dead easy because I only changed the suspension last year. Every thing still greased. Now getting them out last year when I put the Ironman on wasn't as bad as some I have done. I seem to recall I used 6 sided sockets and long extensions to get the big breaker bar on after soaking the top nuts with some pen oil. If you have a nut runner, impact driver, airtool type thing you can save some elbow grease. Also being on a ramp would make a difference to laying on the drive. But all in all, I've had worse trucks to work on. If the plate wasn't removable, I wouldn't even try to undo the top nut. I just use the power hacksaw and cut through the top spindle.

Don't like the adverts? Click here to remove them

Very limited Gary. I am going to wait and see what the new BFG AT looks like. That might be the best option.

I have 2 sets of wheels, both are 10"x 16", one with 305/70 GG AT2s good for asphalt and normal winter / grass & stone tracks and the other with 305/70 BFG MUDs, for.... er... mud.

I'm looking to change the GGs because of sidewall damage, but the bloody treads won't wear out!

Would love to get a set of the new BFG ATs in 315/75s

OK so this kinda crosses with another thread currently running on castor correction and props but I don't want to hijack that even more. I took the front prop off the green one today and measured the UJ offset. It was 34 degrees counter clockwise. Now, the props on an auto are very different to hose on a manual but I don't have anything else to go on, so I reassembled my manual prop to the same 34 degrees. It looked about right. Whilst it was off, I decided to make a 15mm prop spacer. The slip joint was just too extended for my liking. Don't you just love a bit of Boxing Day machining. Damn I love that miller. Look at the fit on the prop flange.

I used some longer bolts obviously. So that's all back on again. I am still completely foxed by prop phasing. So anyone with the answer out there please shout up. I'm fine with the totally straight prop between to aligned flanges. I'm totally clear with a prop between two flanges in the same plane but not vertically aligned. I get UJ working angles, but what doesn't seem to make any sense at all is when the flanges aren't parallel, nor on the same axis - where the remedy is to offset the phase of the prop. Huh?

I looked at the green one today and neither prop is phased straight and I am sure they're original. My manual 80 has a very long rear prop which is arrow straight pretty much from input to output and since realigning it it does seem smoother. Back to You Tube.

I used some longer bolts obviously. So that's all back on again. I am still completely foxed by prop phasing. So anyone with the answer out there please shout up. I'm fine with the totally straight prop between to aligned flanges. I'm totally clear with a prop between two flanges in the same plane but not vertically aligned. I get UJ working angles, but what doesn't seem to make any sense at all is when the flanges aren't parallel, nor on the same axis - where the remedy is to offset the phase of the prop. Huh?

I looked at the green one today and neither prop is phased straight and I am sure they're original. My manual 80 has a very long rear prop which is arrow straight pretty much from input to output and since realigning it it does seem smoother. Back to You Tube.

Blown80

Well-Known Member

Chris, there is lots of info on the Internet, YouTube etc. Aside from correcting and measuring operating angles and flange angles as you noted, the actual phasing should have each axis on the driveshaft itself within 3 degrees as adjusted by the spline rotation.

That is my understanding but am happy to be corrected. I'm not sure why your other vehicle would be 34 degrees out in rotation, doesn't make sense.

That is my understanding but am happy to be corrected. I'm not sure why your other vehicle would be 34 degrees out in rotation, doesn't make sense.

Chris, absolutely everything I have read and watched says that props should be phased in line. The FSM shows only in line props too. If it was supposed to be an 1/8 turn out there would be some sort of data, measurement etc to be able to rebuild a prop that had been pulled apart. But there isn't. Everything says they should be in line. But not one of my 4 props is. This is what is baffling me. Pretty sure the green one is un touched and I am sure that knowing the PO, he would have put it back as it was found if he'd had the prop off for any reason. I set my rear prop in line the other day, which wasn't far out and I could tell an immediate difference. I won't say how fast I got up to, but it was quite fast and I seemed to get there very quickly. All seemed fine. I got back and the next day set my front prop in line as well and although it drove OK, I immediately noticed a speed related dub dub. Due to Christmas day and whatnot, I haven't been able to driver it since. I have set the front to 34 degrees as I said earlier just to get me back to where I was before. I will drive it tomorrow and see if that's gone. Frank is indicating something along the lines of setting a prop off by a few splines is how the 80 is set up to compensate for slightly divergent flanges. I don't see how it works. These types of UJs work on a 90 degree in phase, out of phase relationship. IE you can turn them 180 degrees and they are still in phase but turn them 90 degrees and they are out of phase. Turn them 34 degrees and..... Well and what? They are not in phase but they are not precisely out of phase either, but now they are lopsided. Unless it's a very clever balancing act between phase AND the UJ angle when angles are different at each end.

If you take a prop with a UJ and put an angle on it, the drive flange turns at a constant speed. But the prop speeds up and slows down in a cycle. We know that. If the other end goes virtually straight into the diff, this means the diff end is speeding up and slowing down just like the rest of the shaft. You HAVE to have the same angle at the other end to cancel that. So, is the 34 degrees a cunning way of achieving that? Well, looking at my auto diff flanges today they look parallel to each other so why the heck would you do that?

I'm really looking for a definitive but simple answer. How come the FSM makes no mention of it at all?

If you take a prop with a UJ and put an angle on it, the drive flange turns at a constant speed. But the prop speeds up and slows down in a cycle. We know that. If the other end goes virtually straight into the diff, this means the diff end is speeding up and slowing down just like the rest of the shaft. You HAVE to have the same angle at the other end to cancel that. So, is the 34 degrees a cunning way of achieving that? Well, looking at my auto diff flanges today they look parallel to each other so why the heck would you do that?

I'm really looking for a definitive but simple answer. How come the FSM makes no mention of it at all?

- Joined

- May 13, 2014

- Messages

- 744

- Country Flag

I think you are probably right Chris. The proof would be found either by doing the maths and geometry or by phasing your prop correctly and discovering a vibration which goes when you revert to 34 degrees again. The thing is, much is dependent on the original base line of the components .....

..... The thing which is nagging me though is I can't see the factory engaging in engaging in this level of 'fine tuning' on the production line. Rolls Royce and other top end marques yes, but not the rest. Perhaps your phasing is not original and it is by chance that all is ok .... There are so many variables

..... The thing which is nagging me though is I can't see the factory engaging in engaging in this level of 'fine tuning' on the production line. Rolls Royce and other top end marques yes, but not the rest. Perhaps your phasing is not original and it is by chance that all is ok .... There are so many variables

Gary820

Well-Known Member

I'll make time today to go get my truck and have a look under, I know it's auto but I'd be quite confident saying the props have never been off.

Edit.....

Right just been to work and had a look under mine,

The front prop is 90 degrees out of phase

The rear prop is in phase.

I know it's an auto petrol but I'd say that's how it left the factory.

Edit.....

Right just been to work and had a look under mine,

The front prop is 90 degrees out of phase

The rear prop is in phase.

I know it's an auto petrol but I'd say that's how it left the factory.

Last edited:

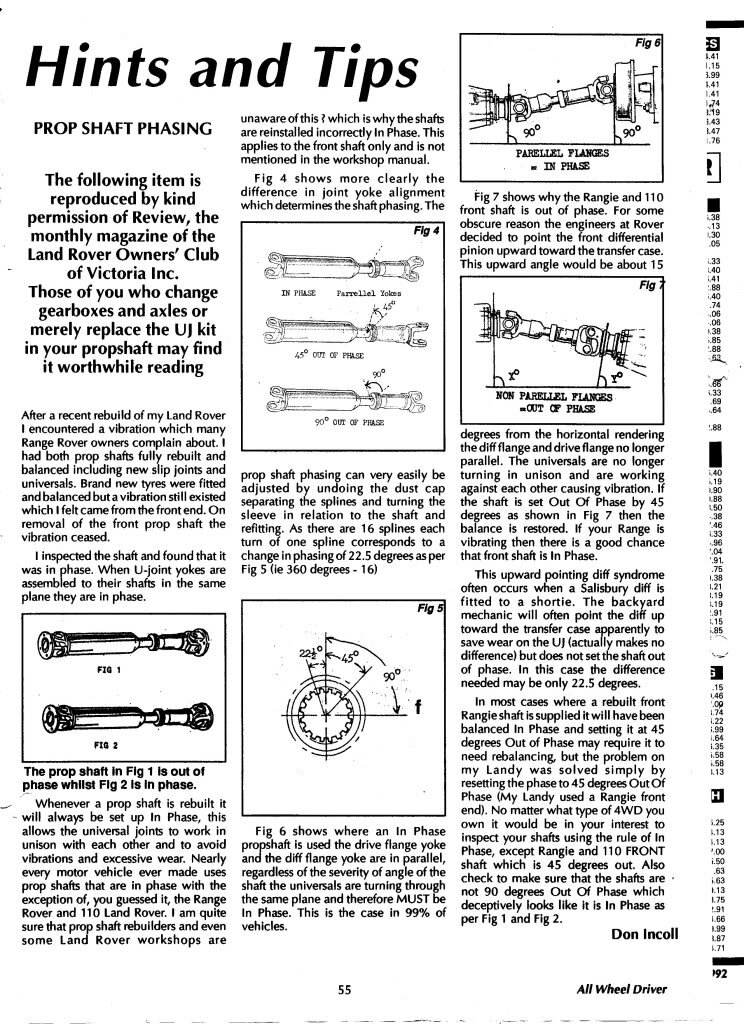

Steve that is EXACTLY what I have going on, on mine. Substitute Landie and Rover for Cruiser (the only time I will ever say that) and that could have been written for mine.

Gary thank you. I think that just adds to the weirdness. In phase and 45 degrees out front to back. My green on is about 3 splines out on the back and as I say now 34 degrees on the front. Been out in the snow today and on a smooth stretch could still hear dub dub dub dub dub dub dub as I speed up. Next job is to drop the front prop and go our CD locked and see what's what. The rear prop must surely be in phase. It's totally straight and the flanges parallel

Yes this is my front set up for sure.

Gary thank you. I think that just adds to the weirdness. In phase and 45 degrees out front to back. My green on is about 3 splines out on the back and as I say now 34 degrees on the front. Been out in the snow today and on a smooth stretch could still hear dub dub dub dub dub dub dub as I speed up. Next job is to drop the front prop and go our CD locked and see what's what. The rear prop must surely be in phase. It's totally straight and the flanges parallel

Yes this is my front set up for sure.

More interesting stuff coming up. It seems that a standard UJ prop must ALWAYS be in phase alignment other than when it shouldn't. Now why did no one say that to start it. It's obvious now!

http://forums.lr4x4.com/index.php?showtopic=48581

http://forums.lr4x4.com/index.php?showtopic=48581

SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

I know that when a vehicle is lifted then the front axle differential 'nose' has to point further up to the transfer box flange or the flange angle is altered slightly by the lift itself. I went to a double cardon on my front diff on the Defender. The front is usually the culprit as for a given lift the shorter front prop has a steeper angle and without castor correction then the flange angle moves further away from vertical. I guess technically it could be a number of other things - for example the TB output bearing, the bearing on the other end of the TB main shaft, u/js, prop input bearing, prop balance weight lost OR prop out of true etc. Castor correction bushes may help to get the flanges parallel again. Perhaps the FSM doesn't mention it is because it is the lift that causes the issues rather than the original alignment.

Steve as to you last and very valid observation, I could go with that but so far no one with an untouched prop has one fully in phase! Other than Gary's rear one that is.

There seems to be nothing wrong with my caster. it drives wonderfully. I have CC plates on so shouldn't need any more correction and certainly not bushes which is something I won't be fitting. But, it has done something as you mention, to the pinion flange angle. I might drop the rear of the rad arm, achieve a better angle but then find the caster is crap. Clearly, there is something very valid to the data you posted earlier about off phasing the prop. I have no vibration - I can just hear this dub dub dub somewhere and it has only appeared since I started fiddling. So first move - drop the prop.

There seems to be nothing wrong with my caster. it drives wonderfully. I have CC plates on so shouldn't need any more correction and certainly not bushes which is something I won't be fitting. But, it has done something as you mention, to the pinion flange angle. I might drop the rear of the rad arm, achieve a better angle but then find the caster is crap. Clearly, there is something very valid to the data you posted earlier about off phasing the prop. I have no vibration - I can just hear this dub dub dub somewhere and it has only appeared since I started fiddling. So first move - drop the prop.

Been quite busy today./ Went up to the unit, mmm nice and dry. Oh pulled another hapless van driver out of a ditch on the way. Got the vehicle up on stands to start with. Securely I might add before any of you safety nazis have a go. In gear, clutch up. Well it was a bit clonky I have to say but it did smooth out a little with some revs on. But still not super smooth.

So I dropped the front prop. Ran it again. I have to say that was very smooth. Clearly the tyres when not in contact with the road do tend to bobble about a bit and bounce back and forth with the backlash in the system. I had all the lockers in which helped.

I took a good look at the front diff pinion and found a very very small amount of play in that so I nipped it and re staked it. I got the front prop on the bench and did some more accurate measurements. The best way to do this is to put a socket in the end of the bearing cap and take a measurement from that. The casting can't be relied upon as being accurate.

Now the trouble here is that I could not get an angle of 45 degrees. I was at something like 34 and the next spline on was 54. So I went with 54, put it all back together and this is what it was like.

View attachment IMG_0946.MOV

All in all pretty smooth. Smoother, I'd say. Went for a spin and it feels good, but given the packed snow and ice here there's nowhere smooth to drive. But 0the dub dub has gone. I wonder if the UJ as it was, was transferring the 'throw' into the slack in the pinion creating the dub dub.

So I dropped the front prop. Ran it again. I have to say that was very smooth. Clearly the tyres when not in contact with the road do tend to bobble about a bit and bounce back and forth with the backlash in the system. I had all the lockers in which helped.

I took a good look at the front diff pinion and found a very very small amount of play in that so I nipped it and re staked it. I got the front prop on the bench and did some more accurate measurements. The best way to do this is to put a socket in the end of the bearing cap and take a measurement from that. The casting can't be relied upon as being accurate.

Now the trouble here is that I could not get an angle of 45 degrees. I was at something like 34 and the next spline on was 54. So I went with 54, put it all back together and this is what it was like.

View attachment IMG_0946.MOV

All in all pretty smooth. Smoother, I'd say. Went for a spin and it feels good, but given the packed snow and ice here there's nowhere smooth to drive. But 0the dub dub has gone. I wonder if the UJ as it was, was transferring the 'throw' into the slack in the pinion creating the dub dub.

Last edited:

Similar threads

- Replies

- 9

- Views

- 323

- Replies

- 16

- Views

- 285

- Replies

- 11

- Views

- 541